Benchtop Autoclave Maintenance: Best Practices for Longevity

A Few Common Issues:

| Common | Likely Causes | Solutions |

|---|---|---|

| Steriliser fails a test | Equipment malfunctions/ operation errors/ incorrect sterilisation procedures. | Improper loading, poor steam quality or incorrect cycle sterilisation |

| Unusual smell from Autoclave | Sterilising biohazardous waste or materials that contain organic matter | Use proper waste containers and clean the Autoclave regularly |

| The load was damaged by an Autoclave | Sterilising biohazardous waste or materials that contain organic matter | Run a specialised liquids cycle that releases pressure slowly instead of all at once |

| Goods aren’t sterilised in an Autoclave | Improper loading, poor steam quality or incorrect cycle sterilisation | Check the manufacturer’s guide, don’t overload a cycle and run a maintenance check |

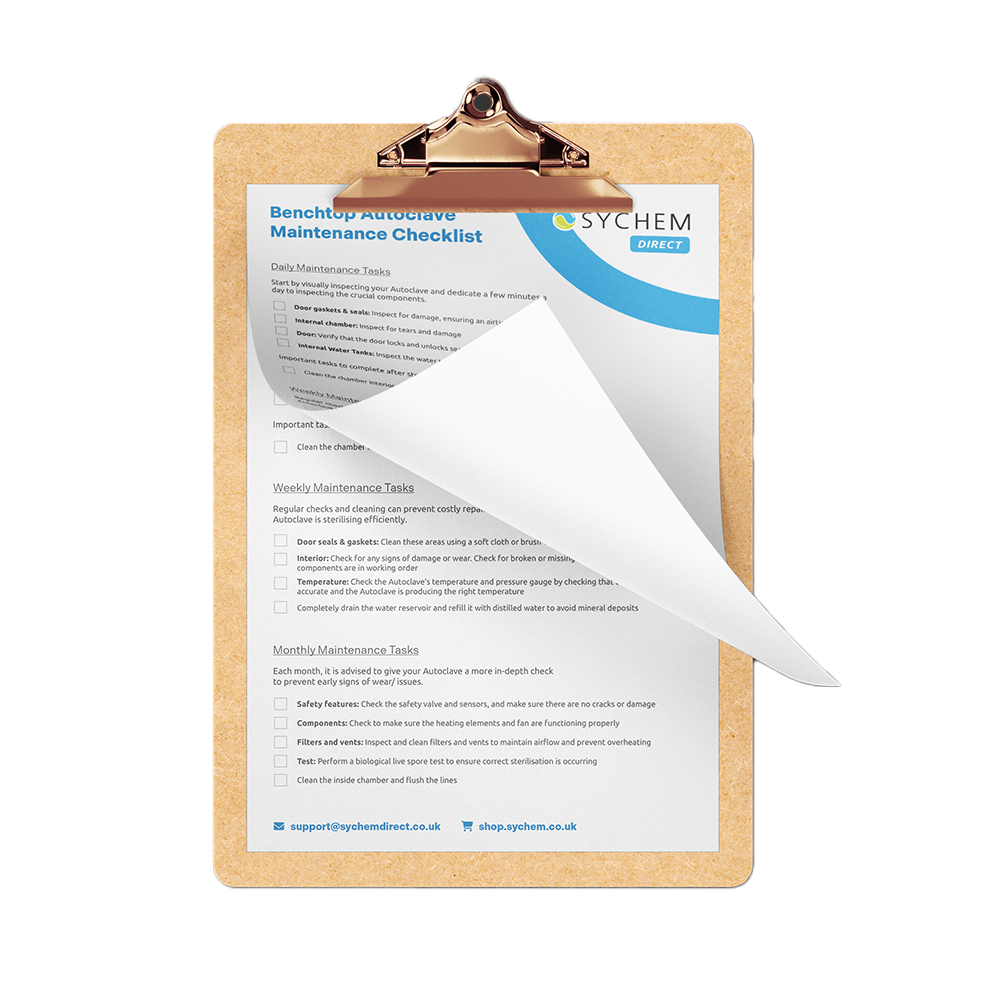

Daily Maintenance Tasks

Start by visually inspecting your Autoclave and dedicate a few minutes a day to inspecting the crucial components.

Door gaskets & seals: Inspect for damage, ensuring an airtight seal

Internal chamber: Inspect for tears and damage

Door: Verify that the door locks and unlocks seamlessly

Internal Water Tanks: Inspect the water tank for potential cracks

Important tasks to complete after sterilisation:

Clean the chamber interior after each use to prevent residue buildup

Weekly Maintenance Tasks

Regular checks and cleaning can prevent costly repairs and ensure the Autoclave is sterilising efficiently.

Door seals & gaskets: Clean these areas using a soft cloth or brush with warm and soapy water

Interior: Check for any signs of damage or wear. Check for broken or missing parts and make sure all components are in working order

Temperature: Check the Autoclave’s temperature and pressure gauge by checking that the readings are accurate and the Autoclave is producing the right temperature

Completely drain the water reservoir and refill it with distilled water to avoid mineral deposits

Monthly Maintenance Tasks

Each month, it is advised to give your Autoclave a more in-depth check to prevent early signs of wear/ issues.

Safety features: Check the safety valve and sensors, and make sure there are no cracks or damage

Components: Check to make sure the heating elements and fan are functioning properly

Filters and vents: Inspect and clean filters and vents to maintain airflow and prevent overheating

Test: Perform a biological live spore test to ensure correct sterilisation is occurring

Clean the inside chamber and flush the lines

Tips for Extending Autoclave Lifespan

Use manufacturers-approved parts and accessories

Avoid overloading the chamber

Maintain a constant cleaning and maintenance schedule

Keep records of maintenance and repairs

Tips for Extending Autoclave Lifespan

Conclusion

To find out more, visit: https://shop.sychem.co.uk/product/benchtop-autoclave-service-validation/

Disclaimer: The content written in this blog is for informational purposes and is only a recommendation. For tailored support, always consult the manufacturer’s guidelines. Sychem Direct accepts no responsibility for misuse or improper handling of equipment. Our engineers and customer service team have you covered for advice and support. Contact us, we’re here to help!